Zeta make fully Automatic Sand preparation with 600 kg batch capacity Savelli, Italy make Intensive mixer deliver 20 tons of mixed sand per Hour.

| Moulding Size | 1000 X 1500 X 500/500mm |

| Casting weight Range | 50 kg to 2500 kg |

| Metal Composition test | SPECTRO Make Spectrometer |

| Mechanical Lab | UTM, Brinell Hardness tester, Impact Strength tester |

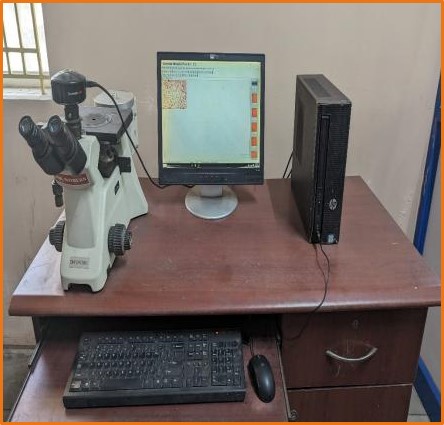

| Metallography | Microscope with Image Analyser |

| Sand Testing | Complete range of Testing instruments for Green Sand and Resin Sand. |

| Mould Size | 650mm X 650 mm X 200/200 mm |

| Production Rate | 40 moulds per Hour |

| In Mould Cooling Time | 1.5 Hours |

| Metal Pouring Method | Mono Rail Ladle pouring |

| Casting Weight Range | 5 kg to 50 kg |

| Casting Material | Grey Iron and SG Iron |

| Mould Size | 950 X 1200 X 400 / 400 mm |

| Production Rate | 30 Moulds per hour |

| In Mould Cooling Time | 2 Hours |

| Metal Pouring Method | Bi Rail Ladle pouring |

| Casting Weight Range | 30 kg to 250 kg. |

| Casting Material | Grey Iron and SG iron |

Inductotherm Make - Medium Frequency IGBT Induction Melting furnace Provisional TriTrek Furnace.

| Crucible capacity | 1500 kg Batch crucible - 2 nos |

| Melt Rate | 1600 kg per hour |

Charge material handling with Electromagnet. Metal pouring by EOT crane and Mono rail arrangement. SG iron treatment with Tandish cover method.

BMD make – Twin Turbine fully automatic PLC controlled

| Shot blasting machine | 500 kg Hanger capacity |

| Cabin Size | 1000 X 1200 X 1000 mm |

| Production Capacity | 3 tons per Hour |

Along with required Finish Grinding machines and Handling forklift and Cranes.

Digital Vernier

| Dimension | Surface table withHeight gauge. |

| 3D measuring system | Based on requirement - outsourced |

| Soundness | Radiography Test - Outsourced |

| Cut Section | In house |

Customer requirement will be arranged in House. From RFQ stage, Customer requirement is recorded in Detail and ensured with complete understanding. Entire operation is professionally managed.

Srivari Ferrocast has tied up with machine shops around foundry and supplies finished components. Also we are engaging to deliver the assemblies for General engineering sectors.

Srivari Ferrocast Private Limited is a part of a diversified business group having interests in Textiles, Engineering, Real Estate, Trading and Education.